Contents

Contents

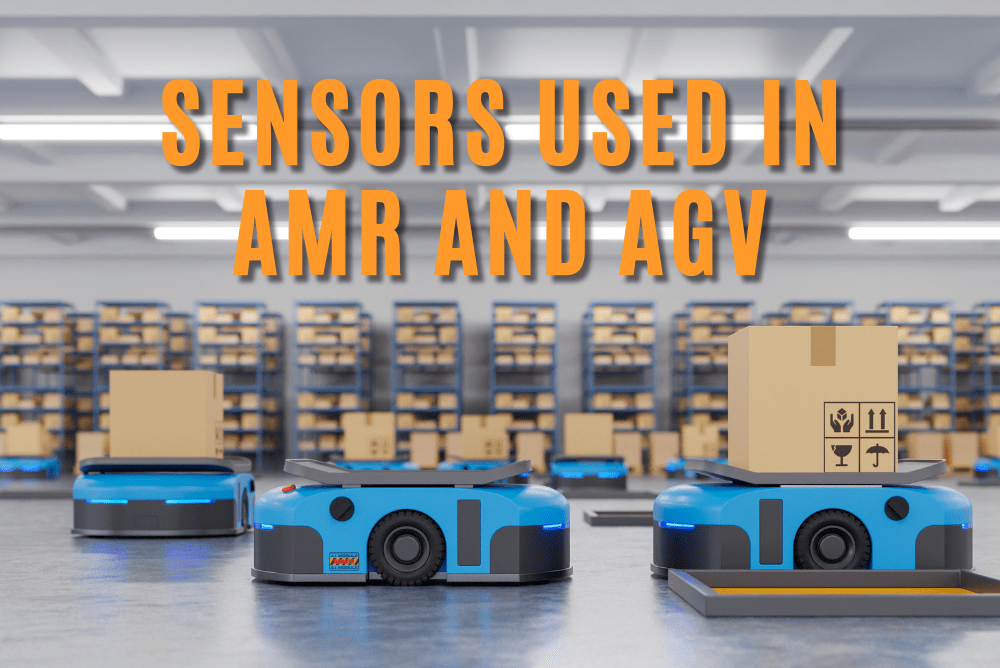

Common sensors found in AMR (Autonomous Mobile Robots) and AGV (Automated Guided Vehicles) include LiDAR, ultrasonic sensors, infrared sensors, and more. In this article, Temas will walk you through how these sensors work and how they benefit AMR and AGV robots.

As industrial automation continues to accelerate, AMRs and AGVs have become indispensable players in the process. While there are notable differences between these two types of robots, both require a variety of advanced sensors to operate smoothly and reliably.

1. LiDAR Sensors

Operating principle:

LiDAR (Light Detection and Ranging) sensors use laser beams to scan the surrounding environment. A basic LiDAR system typically consists of:

- Emitter: Projects laser light at very short wavelengths (nanometers) with energy levels low enough to be eye-safe.

- Scanner: Directs the laser beams in multiple directions.

- Receiver: Detects the reflected laser beams from objects to calculate distances and generate 2D or 3D maps.

LiDAR operates based on the Time-of-Flight (ToF) principle. Specifically, it measures the time taken for a laser beam to travel to an object and back, calculating the distance using:

where:

d: Distance to the object

v: Speed of light (~3 × 10⁸ m/s)

t: Round-trip travel time of the laser beam

By scanning multiple points and stitching them together, LiDAR produces a complete, high-resolution 2D or 3D map.

Roles of LiDAR in AMR/AGV:

- Environment mapping (SLAM – Simultaneous Localization and Mapping)

- Obstacle detection for collision avoidance

- Intelligent navigation in dynamic environments

- Real-time positioning data

2. Ultrasonic Sensors

Operating principle:

Ultrasonic sensors also use the Time-of-Flight principle but emit high-frequency sound waves instead of laser beams. The receiver measures the time it takes for the echo to return, determining the distance to the object.

While ultrasonic sensors and LiDAR serve similar purposes, many autonomous vehicles use both. Ultrasonic sensors can assist LiDAR in situations where interference occurs — for example, with reflective surfaces such as mirrors, glass, stainless steel, or dark, angular floors.

Applications:

- Obstacle detection for navigation

- Emergency stop when a person or object appears

- Detection of objects difficult for LiDAR to perceive

- Often used in sensor fusion to enhance reliability in complex industrial environments

3. IMU (Inertial Measurement Unit)

An IMU is an integrated sensing device that measures and reports acceleration, motion, and orientation. It typically includes:

- Accelerometer: Measures linear acceleration on the X, Y, Z axes; detects translational motion and gravity direction.

- Gyroscope: Measures angular velocity around the X, Y, Z axes; determines tilt, rotation, and turning.

- Magnetometer: Detects Earth’s magnetic field to determine heading; often used to correct gyroscope drift.

In other words, the IMU can track movement, heading, and tilt of an autonomous vehicle. With these parameters, the robot can adjust its route and maintain balance without human intervention.

Although IMUs do not provide absolute position data, they are essential for estimating relative movement — ensuring stability and accuracy when GPS or LiDAR signals are lost or disrupted.

Functions:

- Measure acceleration, tilt, and heading

- Provide backup positioning data when GPS/LiDAR is unstable

- Support balance and steering control

4. Infrared Sensors

Infrared sensors detect or receive infrared light (electromagnetic radiation with wavelengths longer than visible light) to detect objects, measure distances, sense motion, or measure temperature.

Two main types exist:

- Active IR sensors: Emit infrared light toward an object, which reflects back to the receiver. The reflected signal is processed to detect object presence or estimate short-range distances (typically under 80 cm).

- Passive Infrared (PIR) sensors: Do not emit signals; instead, they detect natural infrared radiation from the environment, especially heat from human or animal bodies. PIR sensors trigger when they detect sudden changes in radiation levels (e.g., a person walking past). PIR cannot detect stationary objects, making it unsuitable for static obstacle avoidance.

Active IR sensors are often integrated into AMR and AGV robots, particularly in low-light conditions such as Dark Factory environments.

5. Load Cells

A load cell measures force or load applied to it. When force deforms the load-bearing material (usually metal), strain gauges convert this deformation into an electrical signal, which is then amplified and digitized.

Applications:

- Monitoring cargo weight during transport

- Weight distribution control to prevent tipping

- Detecting irregular cargo placement (e.g., uneven weight distribution)

- Ensuring loads do not exceed maximum capacity

Temas Autonomous Mobile Robot - TMR-300 supports loads of up to 300 kg, making it suitable for a wide range of applications such as in-house logistics, smart warehouses, manufacturing plants, and high-density industrial zones.

6. GPS (Global Positioning System)

GPS is a satellite-based positioning system developed by the U.S. Department of Defense. It enables precise determination of a device’s location anywhere on Earth, at any time, under any weather conditions.

To calculate its latitude, longitude, and altitude, a GPS device integrated into an AMR or AGV must receive signals from at least four satellites.

Applications:

- Outdoor AMR/AGV operations in logistics yards, airports, or open areas.

- Combined with IMU for improved positioning accuracy in warehouses, tunnels, or areas with metal structures or weak signals.

7. Magnetic Sensors

Magnetic sensors emit a high-frequency alternating magnetic field. When a conductive metal object enters the field, eddy currents are induced on the object’s surface, altering the sensor’s internal oscillation circuit — producing an ON/OFF output signal.

Magnetic sensors are commonly integrated into traditional AGVs, guiding them along pre-installed magnetic tape paths. This is a key difference between AMRs and AGVs: when factory or warehouse layouts change, AGVs require more time for reconfiguration and setup.

Key Features and Limitations of Each Sensor

Below is a summary table of the key features and considerations for commonly used sensors in AMR/AGV systems:

|

Sensor Type |

Key Features |

Considerations |

|

LiDAR |

High accuracy, wide range, works well under varying light conditions, distinguishes static/dynamic objects |

Higher cost, may be affected by dust or harsh environmental conditions |

|

Ultrasonic |

Easy integration, unaffected by light |

Lower accuracy than LiDAR, susceptible to interference in noisy or high-vibration environments |

|

IMU |

Provides precise real-time motion data, compact size |

Requires calibration, works best when integrated with other sensors |

|

Infrared (IR) |

Low power consumption, fast short-range obstacle detection |

Affected by strong light, limited range |

|

Loadcell |

Accurate weight/load measurement |

Sensitive to shocks, requires careful calibration |

|

GPS |

Global positioning, ideal for outdoor use, no extra infrastructure required |

Poor performance indoors or underground, signal blocked by metal structures or weak reception |

|

Magnetic |

Reliable tape-based navigation, resistant to dust/water |

Inflexible, unsuitable for complex environments, difficult to adapt to layout changes |

No single sensor is “all-powerful.” In practice, AMRs and AGVs use a combination of sensors, each fulfilling specific roles and complementing one another. The integration of LiDAR, cameras, IMUs, ultrasonic sensors, and other safety sensors is the key to building intelligent, adaptable, and safe robotic systems for future factories and warehouses.

🔎 Looking for AMR/AGV solutions for your factory or smart warehouse?

Contact Temas’ team of experts for tailored autonomous robot solutions that best fit your production and logistics needs.

Read more

Read more