Nội dung

Nội dung

- What Is ICT (In-Circuit Test)?

- What Is FCT (Functional Circuit Test)?

- Where ICT and FCT Fit in the Production Line

- Challenges in ICT and FCT Processes

- Automation Solutions for ICT and FCT

- Techman AI Cobot for Flexible Handling and Inspection

- Visco Machine Vision Inspection System for Fast and Accurate Analysis

- Temas AMR for Automated PCB Tray Transportation

In electronics manufacturing, ensuring PCB quality and stability is a critical factor that directly impacts productivity and factory reputation. Among the most common inspection stages today are ICT (In-Circuit Test) and FCT (Functional Test). These are essential steps before final assembly or shipment.

As production volumes increase and quality requirements become stricter, automating ICT and FCT stations has become inevitable. Automation helps reduce human errors, increase test throughput, and significantly improve data traceability.

What Is ICT (In-Circuit Test)?

ICT (In-Circuit Test) is a process used to inspect electronic components and circuits on a PCB, typically performed after AOI and SPI in the SMT line.

The primary purpose of ICT is to detect:

- Component defects

- Incorrect component values

- Soldering issues

- Short circuits and open circuits

ICT Working Principle

An ICT system uses test probes that make direct contact with designated test points on the PCB. This is commonly known as a bed-of-nails tester.

Bed-of-nails tester

During contact, the system measures electrical parameters such as resistance, capacitance, voltage, and current to verify whether each component meets its specifications.

In addition to traditional bed-of-nails fixtures, modern ICT systems also use Flying Probe technology. Flying Probe systems use movable probes and do not require dedicated fixtures. This approach is especially suitable for high-mix production environments in Vietnam, as it reduces fixture costs and shortens model changeover time from hours to just minutes.

Flying Probe testing

Objectives of ICT

- Component verification: Confirm correct component values such as resistors, capacitors, and inductors, and verify proper placement.

- Short and open detection: Identify solder bridges, missing solder joints, and broken traces.

- Polarity check: Verify correct orientation of polarized components such as diodes, electrolytic capacitors, and ICs.

- Component quality assessment: Detect damaged or out-of-spec components caused during handling or processing.

Practical Examples

- Verifying whether capacitors have the correct value and are placed correctly.

- Measuring resistance at circuit nodes to detect shorts or opens.

- Checking the orientation of diodes and transistors.

ICT helps identify defects early, before the PCB moves to final assembly, resulting in significant savings in rework and recall costs.

What Is FCT (Functional Circuit Test)?

FCT (Functional Circuit Test) verifies the actual operating behavior of an electronic product after the PCB is powered on, firmware is programmed, and all connections are established.

FCT can be performed at two levels:

- Board-level FCT: Testing the bare PCB

- System-level FCT: Testing after full assembly

While ICT focuses on components and circuits, FCT validates real functional performance.

Objectives of FCT

- Ensure the PCB operates according to design logic and specifications.

- Perform input and output testing

- Verify communication interfaces such as UART, CAN, Ethernet, and USB

- Test peripherals such as LEDs, sensors, relays, motors, and displays.

Practical Examples

- Verifying that a motor control board drives a fan at the correct speed when a PWM signal is applied.

- Checking whether a temperature sensor module responds accurately to environmental changes.

FCT is typically performed after ICT and before packaging or final assembly.

Where ICT and FCT Fit in the Production Line

In most electronics factories in Vietnam, ICT and FCT are located at the end of the SMT line or after module assembly.

| Process Stage | Activity | Notes |

| SMT Line | Component placement, reflow soldering, AOI | Preliminary visual inspection |

| ICT | Electrical testing such as resistance, capacitance, shorts | After AOI |

| FCT | Power-on and functional testing | After ICT |

| Final Assembly | Enclosure assembly and system test | Before packaging |

Challenges in ICT and FCT Processes

Despite being widely used, ICT and FCT still face several practical challenges:

- Manual handling: Operators loading and unloading PCBs may cause misalignment, board warping, or damage to test pins.

- Limited throughput: Manual operation limits speed and makes scaling difficult as production volume increases

- Risk of PCB damage: Boards are vulnerable to bending, scratches, and ESD during handling.

- High fixture cost and long changeover time: Bed-of-nails fixtures are model-specific. Flying Probe reduces fixture dependency but still benefits from automation for speed, accuracy, and traceability.

- Poor data integration: Test data is often not fully connected to MES or traceability systems.

- Limited visual inspection: ICT and FCT focus on electrical parameters and may miss visual defects such as misaligned components or solder surface issues.

- Safety and ESD risks: Manual handling near powered boards increases electrical and ESD hazards.

As a result, demand for ICT and FCT automation continues to grow.

Automation Solutions for ICT and FCT

Temas provides automation solutions for electronic testing processes by integrating Techman AI collaborative robots, Visco machine vision systems, and Temas AMR autonomous mobile robots.

Techman AI Cobot for Flexible Handling and Inspection

Techman AI collaborative robots can fully replace manual operations in ICT and FCT processes:

- Pick PCB from tray and place it onto the fixture

- Start the test automatically

- Remove the PCB after testing and sort OK and NG boards into separate trays.

- With built-in AI Vision, the robot can also perform visual inspections, such as detecting incorrect LED status, missing components, or solder surface defects.

Techman Robot with bed-of-nails testing - Image: WiredWorkers

Video: PCB Testing cobot | Techman Robot

Advantages of Techman AI Cobot in ICT and FCT

- Precise PCB handling with a 6-axis structure

- Flexible access to fixtures from multiple angles

- Accurate placement on bed-of-nails fixtures or Flying Probe test tables.

- Reduced PCB bending and test pin wear

- Compatible with various fixtures without complex mechanical mechanisms

- AI camera integrated directly on the robot arm

- No need for external cameras.

- Fast visual inspection during ICT and FCT:

- Misaligned or missing components

- Incorrect LED status

- Improper socket or connector insertion.

- Lower hardware cost and simpler system integration.

- Easy model changeover for high-mix, low-volume production.

- QR code reading on PCBs.

- Board marking after inspection.

Built-in camera with AI Vision

- TM Landmark technology for precise handling even with misaligned PCBs

- AI Vision combined with TM Landmark identifies the actual PCB position.

- Automatic trajectory correction during pick-and-place.

- Ideal for Flying Probe testing.

- No requirement for perfectly aligned trays.

- Well-suited for real-world factory environments.

Unique TM Landmark technology

By integrating AI Vision and on-arm cameras, Techman cobots help manufacturers:

- Significantly reduce human errors and PCB damage.

- Maintain stable testing processes with 24/7 operation.

- Easily adapt to frequent model changes in high-mix production.

Temas has successfully deployed multiple projects where Techman robots perform automated ICT and FCT operations in electronics factories across Vietnam.

Product: Techman AI Cobot

Visco Machine Vision Inspection System for Fast and Accurate Analysis

VVisco is an industrial vision inspection system designed for visual inspection applications.

In ICT and FCT processes, Visco system can:

- Determine precise positioning for robot or handling mechanisms.

- Inspect test pins and fixtures for cleanliness and proper contact.

- Analyze connectors, sockets, LED states, and LCD displays during FCT.

- Capture image data for traceability.

By combining advanced algorithms with industrial lighting such as ring, coaxial, and diffuse illumination, Visco vision inspection system ensures stable performance even in challenging factory environments.

Visco Machine Vision Inspection System

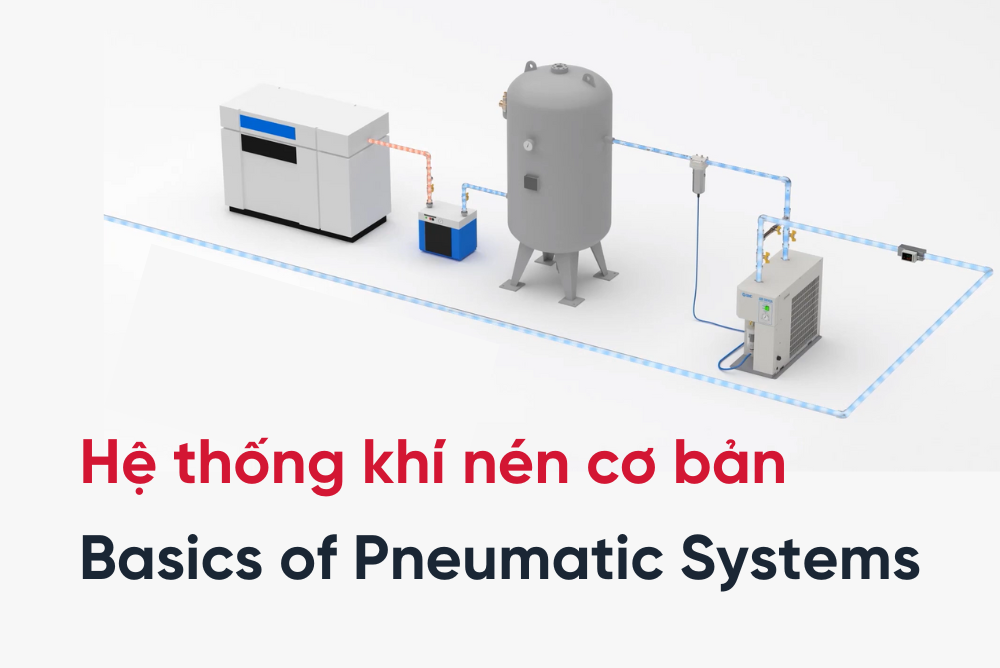

Temas AMR for Automated PCB Tray Transportation

In medium to large electronics factories, ICT and FCT areas are often physically separated to optimize layout and material flow. Temas AMR provides an effective solution for automating PCB tray transportation between test stations

Applications in ICT and FCT

- Transport PCB trays from AOI to ICT.

- Transfer tested boards from ICT to FCT.

- Return OK and NG trays to sorting or packaging areas.

Advantages of Temas AMR

- High operational stability

- Designed for continuous 24/7 operation

- Supports charging stations or automatic charging.

- Integrated UPS to prevent production interruptions.

- Advanced safety and obstacle avoidance

- Equipped with LiDAR and ultrasonic safety sensors.

- Automatically stops and avoids people and equipment.

- High accuracy and repeatability

- Precise navigation to ICT and FCT stations.

- Stable docking positions for integration with robots or conveyors.

- Easy scalability

- Supports multiple test stations.

- Multiple AMRs can operate simultaneously under a single control system.

- Modular hardware and software design for easy deployment and maintenance.

ICT and FCT are two core inspection steps in electronics manufacturing, ensuring product quality before delivery to end users.

To achieve high productivity, consistent accuracy, and full data traceability, manufacturers need to automate their testing processes using modern technologies.

Temas provides a comprehensive automation solution for ICT and FCT, including:

- Techman AI Cobot: for intelligent handling and AI-based visual inspection.

- Visco industrial vision inspection systems for fast and accurate visual defect detection

- Temas AMR for automated PCB transportation between test areas

Contact Temas to receive expert consultation on the most suitable ICT and FCT automation solution for your factory.

Read more

Read more