Nội dung

Nội dung

In high-volume server manufacturing, even a single missing or misaligned component can lead to after-sales claims, product recalls, or serious damage to brand reputation.

This case study shares how a large-scale server manufacturer in Taiwan applied an AI cobot to automate server visual inspection, replacing manual checks and significantly improving quality consistency before shipment.

Customer Background

The customer is a large electronics manufacturer in Taiwan specializing in high-volume server production. At the final stage before delivery, 100 percent of servers must undergo visual inspection to verify the presence, installation position, and condition of critical components, including:

- Connectors

- Cable ties

- Protective caps

- Batteries

- Cable routing

- SSDs

- Screws

As server configurations become increasingly complex and quality requirements more stringent, final inspection has turned into a major bottleneck on the production line. The customer needed a highly reliable and scalable inspection system that could:

- Perform stable and consistent inspection across multiple component types.

- Reduce human-induced errors

- Shorten inspection time

- Ensure consistent server quality before shipment

Challenge: Limitations of Manual Inspection

Despite having standard operating procedures (SOPs) in place, visual inspection by human operators still faced several issues:

- Fatigue-related errors: Repetitive inspection tasks over long shifts increase operator fatigue, leading to missed minor defects.

- Inconsistent judgment criteria: Inspection standards vary between operators, causing quality fluctuations and reduced consistency.

- Lack of inspection traceability: No systematic way to record, store, or review inspection results.

- High component complexity: Numerous components and configuration variants make standardization difficult.

The customer urgently needed an automated inspection solution that could deliver repeatable accuracy while reducing dependence on manual labor.

Visual Inspection Solution for Servers

To improve inspection efficiency, the proposed solution was the use of a Techman AI cobot equipped with an integrated vision system and TM AI+ Trainer software.

Inspection Workflow

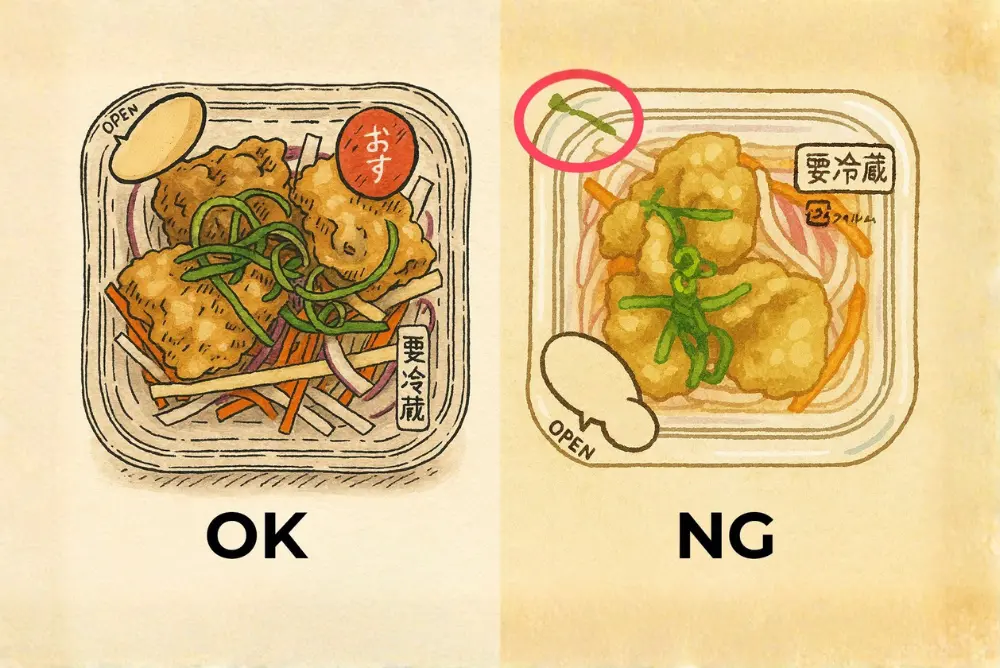

- The AI model is trained using labeled image datasets classified as OK or NG, based on multiple server component samples.

- The cobot captures images of the entire server at the inspection station.

- The AI model classifies each inspection area, such as connectors, batteries, and cable ties, to determine whether components are present, correctly positioned, or abnormal.

- If an NG condition is detected, the system immediately flags the unit and removes it from the line for further handling.

Key Inspection Items

- Detection of connectors, protective caps, and cable ties

- Verification of battery presence and cable routing

- Confirmation of SSDs and screws.

AI Model Training

- AI function used: Classification. This is one of the built-in AI functions in Techman AI Vision. In addition to Classification, the system also supports Object Detection, Semantic Segmentation, Anomaly Detection, AI OCR, and Instance Segmentation.

- Data source: Real images captured directly from the production line.

- Training method: Supervised learning using labeled OK and NG images. Each component region is trained independently to ensure high classification accuracy.

Results and Benefits

Implementing the Techman AI cobot delivered clear improvements:

- Parallel multi-point inspection: Multiple components are inspected simultaneously, reducing overall cycle time.

- High inspection consistency: AI delivers uniform inspection judgments, independent of shifts or operators.

- Full traceability: All inspection results are digitally recorded and stored for QA tracking and analysis.

- Reduced rework and after-sales risk: Only compliant servers are shipped, minimizing post-delivery issues.

- Lower reliance on manual labor: Human errors are reduced, and inspection resources are optimized.

- Scalable solution: The AI inspection model can be extended to other packaging or inspection scenarios on the production line.

By deploying a TM AI cobot for pre-shipment server visual inspection, the customer successfully replaced time-consuming manual checks with a stable, traceable, and scalable AI-based inspection system.

This solution not only improves inspection efficiency and data traceability but also ensures higher final-stage product quality, strengthening the manufacturer’s reputation and server production capability.

We provide Techman AI cobot solutions in Vietnam, supporting both similar applications and customized inspection setups tailored to each factory’s requirements. Contact us to arrange an on-site trial of the Techman AI cobot solution at your factory.

![MOON LIFTER - SUCCESS STORY OF ONCHI SHOKUHIN CO., LTD. [KYOTO]](https://www.temas.vn/filemanage/Case Stories/Unipulse/Moon Lifter/cau_chuyen_thanh_cong_moon_lifter_3.jpg)

Read more

Read more