Contents

Contents

Climate change is one of today’s most pressing and critical challenges, with wide-ranging impacts across many sectors—including agriculture. Rising temperatures, unpredictable rainfall patterns, and increasingly frequent extreme weather events are making it more difficult for many crops to maintain yield, quality, and sustainability.

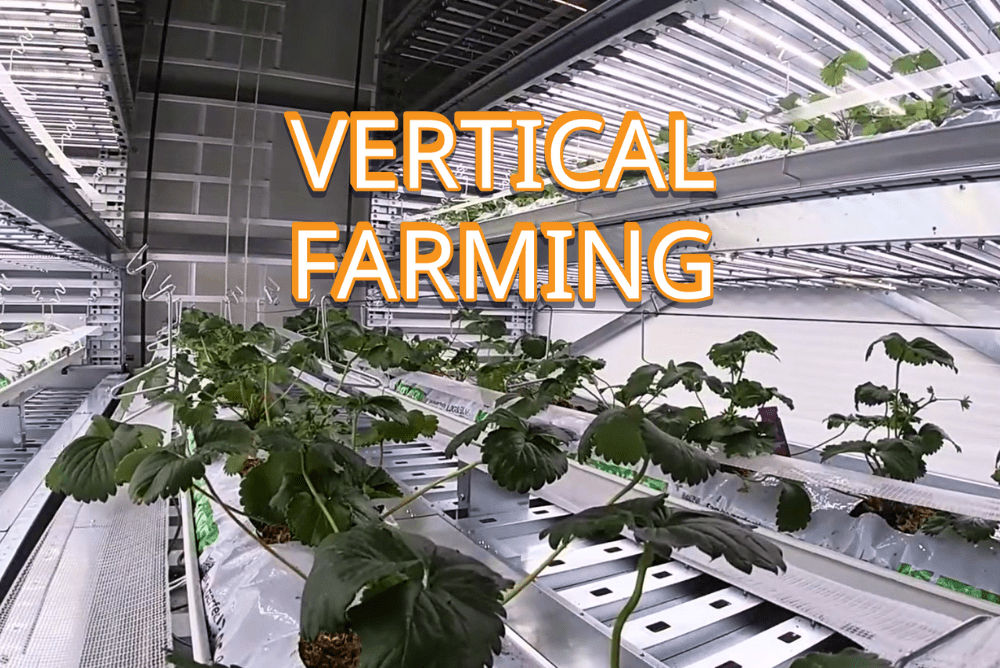

This situation creates an urgent need for innovative and sustainable solutions that can ensure the stable quality of plantlets, independent of external environmental conditions. One such solution is the smart warehouse, which enables cultivation in a fully controlled environment, isolated from external factors such as climate, humidity, and human interaction.

Micropropagation in Smart Warehouses: A Solution to Climate Challenges

Micropropagation is a technique for growing new plants in sterile conditions by using small plant tissues or cells to generate complete plantlets.

The success of micropropagation depends almost entirely on the precise control of critical environmental factors such as temperature, humidity, and light intensity. These parameters must be maintained within optimal ranges to ensure healthy and uniform plant growth.

Proper control of these conditions brings several key benefits:

- High-quality plants

- Reduced production time

- Clean, pathogen-free plantlets

- Stable, high genetic quality

Modula Biotech Tower

The integration of micropropagation with vertical smart warehouses opens new directions for modern agriculture. This process can be illustrated as follows:

Modula Biotech Tower plays a key role in the early stages of plant micropropagation. This smart warehouse fully controls the necessary conditions for living tissues to trigger cell division, form structures such as shoots and roots, and eventually develop into complete, healthy plantlets.

Once high-quality plantlets are produced by the Modula Biotech Tower, they are transferred to specialized growing environments such as Modula Farm. This smart warehouse supplies CO₂, water, and a fertigation system, allowing the young plants to continue growing robustly.

Modula Farm

With this smart warehousing system, we can enhance sustainability and production efficiency while effectively responding to climate challenges and the increasing demand for clean food sources.

Comparing Modula Farm and Biotech Tower

Modula Farm features an integrated system designed to ensure optimal growing conditions, combining precise environmental controls with built-in irrigation. This vertical automated warehouse can reach up to 10 meters in height, maximizing space utilization and enabling efficient and sustainable cultivation of large quantities of plant materials.

With various tray configurations, Modula Farm offers the following storage capacities:

- Up to 5,940 trays (Configuration 1)

- 6,600 trays (Configuration 2)

- Up to 11,800 trays with full structural depth (Configuration 3)

Each tray can hold up to 40 plantlets. Capacity can be further increased depending on whether dividers are used between cells. At maximum depth, configurations 1 and 2 reach 9,917 and 11,906 trays, respectively.

The same principle applies to culture jar storage, which can be arranged in four different configurations—with or without dividers—to increase capacity and improve spatial flexibility.

Additionally, Modula Farm is equipped with an integrated irrigation system—a key differentiator from the Modula Biotech Tower, which is primarily designed for micropropagation and nursery tasks within lab or production environments.

Modula Farm with built-in irrigation system

Both Modula Farm and Modula Biotech Tower are core components of the Modula ecosystem, designed to support innovative and sustainable agriculture. Below is a comparison table of the two systems:

Comparison Table: Modula Farm vs. Modula Biotech Tower

|

Feature |

Modula Farm |

Modula Biotech Tower |

|

Fertigation system |

Yes, integrated to ensure optimal water and nutrient supply |

No, not designed for micropropagation or nursery use |

|

CO₂ usage |

Yes, essential for maximizing yield |

Not typically required |

|

Light type |

High intensity, full-spectrum white or red spectrum (optional) |

Low intensity, mostly cool or neutral white light |

|

Biological control and pollinators |

Yes, recommended use of bumblebees and predatory insects |

No, surface and air sterilization prioritized to prevent contamination |

|

Day/night performance management |

Yes, optimized for growth cycles |

Minimal physiological variation |

|

Main applications |

Edible plants, herbs, and other agricultural crops |

Advanced micropropagation, grafting, insect farming, and mushroom cultivation |

High Efficiency, Sustainability, and Productivity with Modula

To address the challenges of climate change and the growing need for high-quality, sustainable agricultural production, advanced, reliable, and high-performance technologies are essential. Vertical micropropagation and smart warehousing are central to this transformation, helping improve efficiency, conserve resources, and maintain high-quality standards.

Achieving high efficiency

By integrating precise environmental control technologies with intelligent space optimization, Modula's solutions are becoming strategic partners for companies and laboratories seeking to leverage innovation and sustainability as competitive advantages. Modula Farm and Biotech Tower offer fully controlled, flexible, and scalable cultivation environments—ideal for next-generation farming models.

Investing in these new technologies not only enhances productivity and plant quality, but also represents a vital step toward a more responsible and adaptable agricultural model—ready to face today’s environmental and market challenges, and those of the future.

Reference: Modula Smart Warehouse

Read more

Read more