Contents

Contents

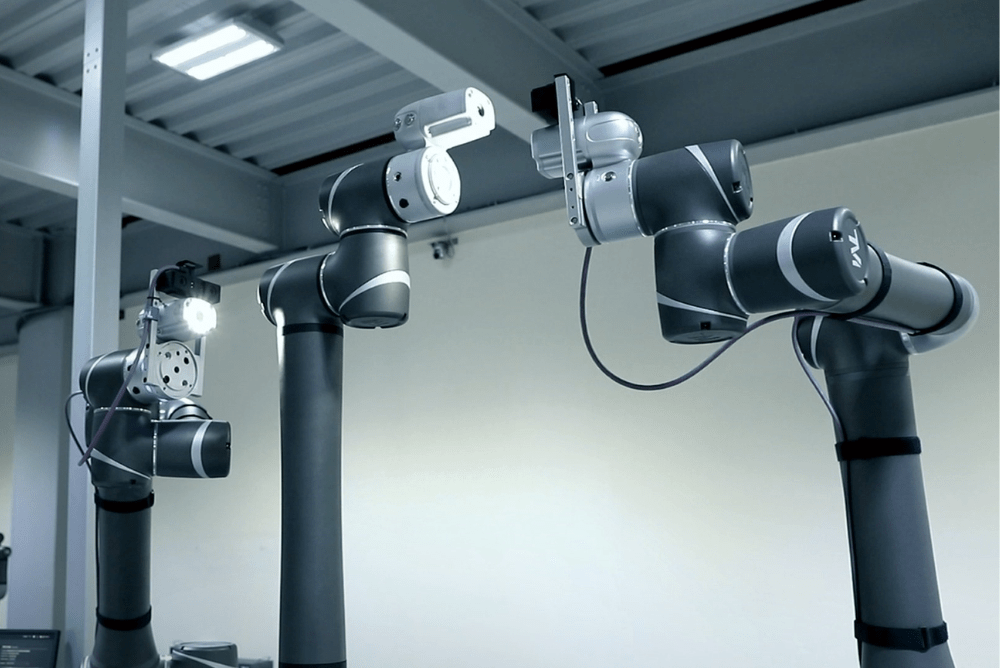

What is a Cobot?

A cobot, or collaborative robot, is a type of robot designed to work safely and efficiently alongside humans in industrial and manufacturing environments. Unlike traditional industrial robots that operate independently in isolated zones, cobots are engineered to collaborate directly with humans without the need for physical safety barriers.

Seamlessly integrating into human-centric workflows, cobots enhance productivity while maintaining safety, making them a revolutionary solution in modern automation.

Cobots also act as a bridge between human creativity and machine precision, solidifying their role as the next major trend in the field of automation.

Top Benefits of Using Collaborative Robots (Cobots)

Cobots offer a wide range of outstanding advantages that make them a top choice in automation:

- Scalability: Cobots can easily adapt to various business sizes, from small startups to large enterprises.

- Cost-Effectiveness: Compared to traditional robots, cobots have a lower upfront investment and require less complex infrastructure, reducing financial barriers.

- Safety: Equipped with advanced sensors and safety features, cobots can work seamlessly with humans without physical safety fences.

- Flexibility: Cobots can be quickly reprogrammed to perform multiple tasks, ensuring consistent operation across diverse production processes.

These benefits help cobots boost productivity and drive innovation across many industries.

The Rapid Adoption of Cobot Automation

The adoption of cobot automation is accelerating as businesses worldwide recognize the transformative potential of this technology. Industries such as manufacturing, logistics, and packaging are increasingly leveraging cobots to maximize efficiency and meet growing production demands.

Collaborative robots offer the ideal balance between cost, adaptability, and safety—particularly suitable for small and medium-sized enterprises (SMEs) aiming to automate without overhauling their entire operational systems.

The global cobot market was valued at approximately USD 1.9 billion in 2024 and is projected to reach USD 11.8 billion by 2030, with a compound annual growth rate (CAGR) of 35.2%. A significant portion of this growth is driven by SMEs adopting cobots due to their ease of use and cost-effectiveness, making them a viable alternative to traditional industrial robots.

(Data source: Collaborative Robot Industry Growth Analysis, Market Share, Statistics & Forecast Report by Payload)

The surge in cobot adoption highlights a major shift in the landscape of industrial automation.

5 Key Industries Benefiting from Cobot-Driven Production

Cobot automation is redefining various industries by enhancing efficiency and precision across numerous applications:

- Manufacturing: Cobots support assembly, welding, and quality inspection processes, working side-by-side with humans to boost productivity. For example, electronics manufacturers use cobots for high-precision tasks such as component soldering and product quality control.

- Logistics & Warehousing: Cobots play a key role in sorting, picking and placing items, and palletizing, reducing manual labor and increasing handling efficiency. Companies like Amazon have integrated cobots to optimize order fulfillment and warehouse management.

- Packaging: Cobots label, seal boxes, and sort products with speed and precision. In the food and beverage industry, cobots ensure consistent packaging quality while minimizing errors and waste.

- Healthcare: Cobots are increasingly used in tasks like lab automation, medical device assembly, and patient rehabilitation support. Thanks to their precision and built-in safety features, cobots are ideal for processes that require high stability.

By integrating cobots into their workflows, these industries not only achieve higher productivity but also improve quality control and reduce costs—underscoring the transformative power of collaborative robotics.

How Cobots Empower Small and Medium Enterprises (SMEs)

Cobots are helping SMEs advance automation by offering affordable, tailored solutions:

- Cost Optimization: With low initial investment and simple maintenance, cobots make automation accessible without requiring major infrastructure changes.

- Ease of Deployment: User-friendly programming enables cobots to be quickly integrated into existing processes, minimizing training time and operational disruption.

- Efficiency: A packaging company in Europe reduced labor costs by 30% using cobots for labeling, while an electronics manufacturer improved product quality and output with cobot-assisted soldering.

By addressing SME-specific challenges, cobots help smaller businesses boost efficiency, compete with larger players, and remain agile in a dynamic market.

The Future of Cobot Automation

The future of cobots is promising, driven by technological advances and expanding applications across new industries:

- AI-Integrated Cobots: Artificial intelligence allows cobots to recognize patterns, predict operational needs, and self-optimize processes—minimizing downtime and increasing efficiency.

- Cloud-Connected Cobots: Integration with cloud technology enables real-time data monitoring, predictive maintenance, and remote process optimization.

- Diverse Applications Across Industries: In healthcare, cobots assist with precision surgeries, lab automation, and rehabilitation. In agriculture, they support planting, harvesting, and crop monitoring—enhancing productivity and sustainability.

With continuous innovation, collaborative robots will become increasingly intelligent and efficient, cementing their role as essential tools in industrial automation.

At Temas, we not only provide cutting-edge cobots but also offer a team of experienced automation engineers to deliver the best-fit cobot solutions tailored to your business needs. Contact us today for a free cobot trial experience.

Our Distributed Cobot Lineup: Techman AI Collaborative Robots

Read more

Read more