Technical Information

Types

- Compact Series SKR20

- Compact Series SKR26

- Compact Series SKR33

- Compact Series SKR46

- Compact Series SKR55

- Compact Series SKR65

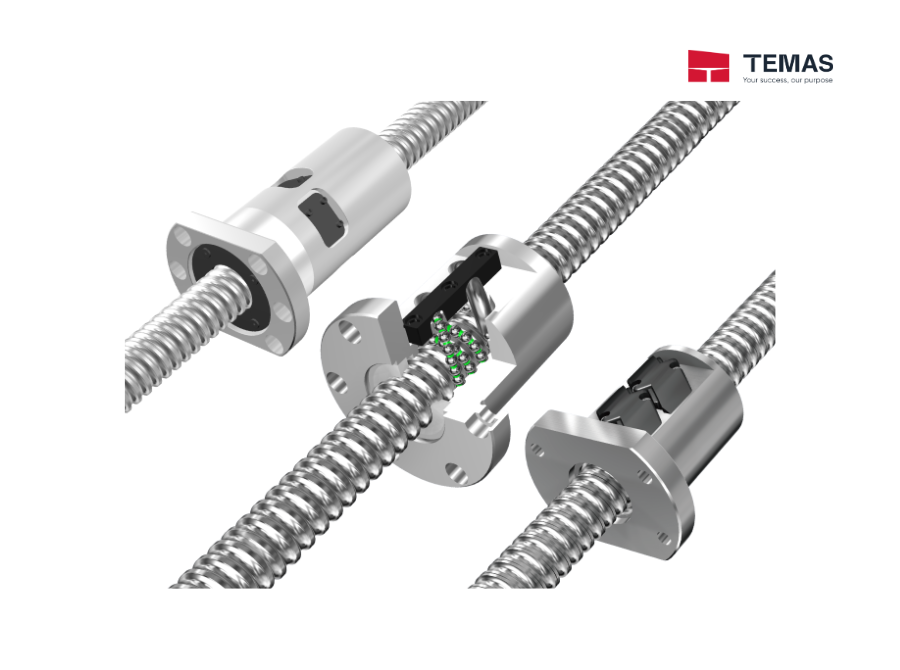

Structure and Features

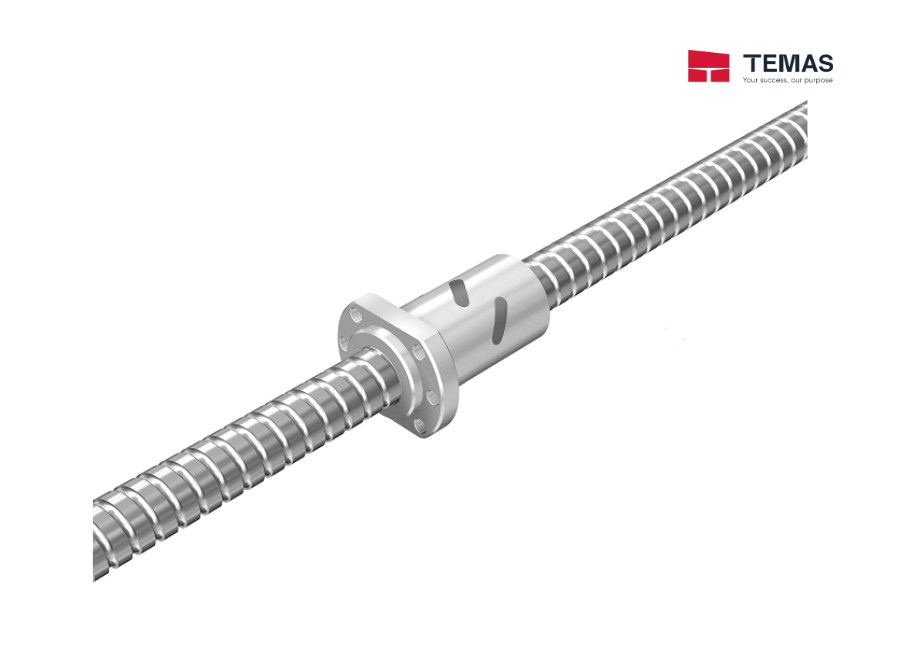

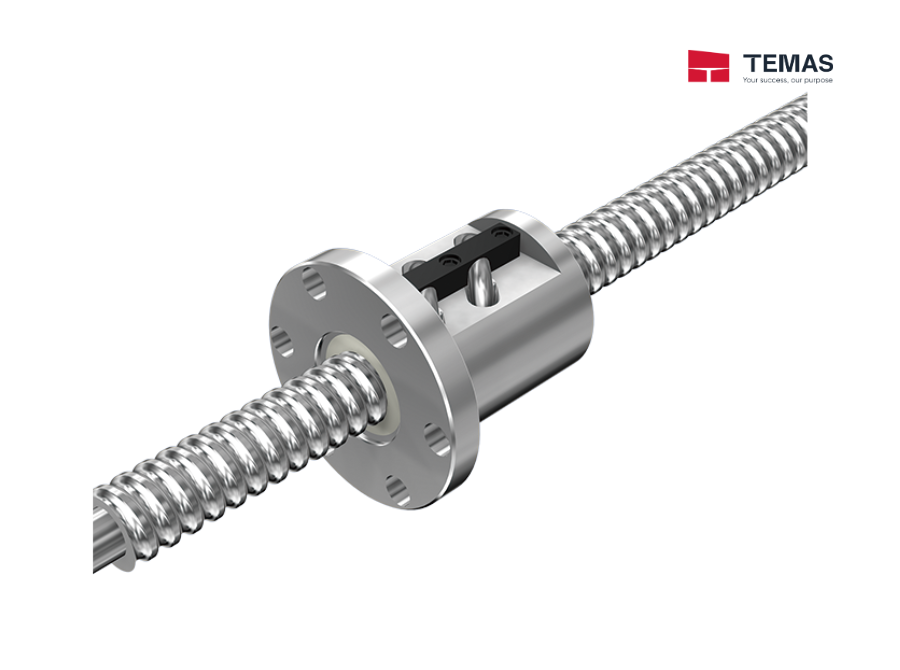

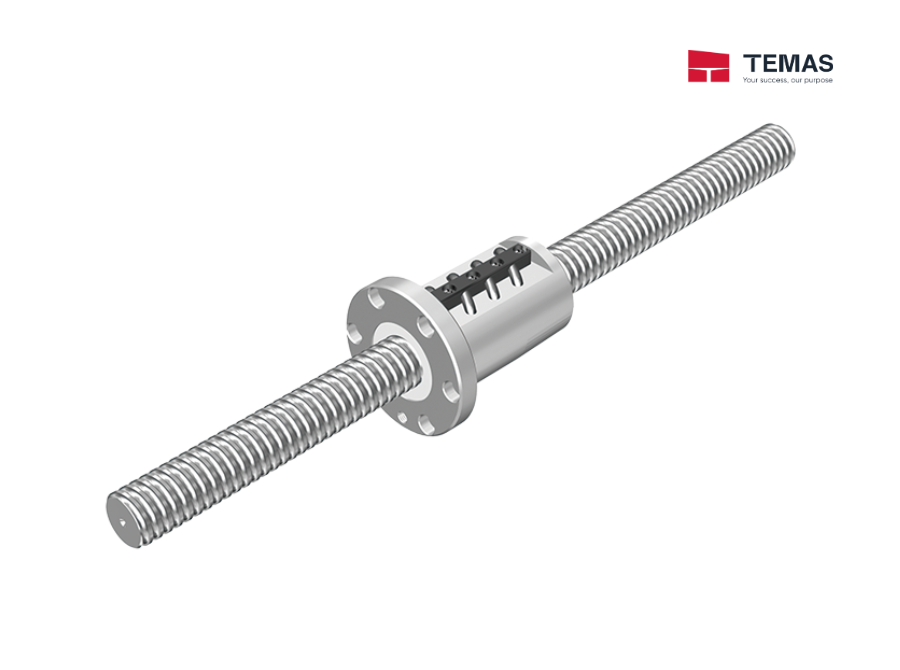

Caged Ball Linear Motion Guide Actuator model SKR is a compact actuator that has a inner block consisting of Linear Motion blocks and a ball screw nut integrated inside a U-shaped outer rail. In addition, this model achieves high speed operation, lower noise and longer-term maintenance-free operation by using ball cages in the Linear Motion Guide units and the Ball Screw unit. (A ball cage is used only for the Linear Motion guide section of models SKR20 and SKR26 and the ball screws are fitted with QZ lubricators.)

4-way Equal Load

Each row of balls is arranged at a contact angle of 45° so that the rated load on the inner block is uniform under loads applied to the inner block in the four directions (radial, reverse radial and lateral directions). As a result, model SKR can be used in any mounting orientation.

High Rigidity

Use of an outer rail with a U-shaped cross section increases the rigidity with respect to moment and torsion.

High Accuracy

Since the linear guide section consists of 4 rows of circular-arc grooves that enable balls to smoothly move even under a preload, a highly rigid guide with no clearance is achieved. Additionally, variation in frictional resistance caused by load fluctuation is minimized, allowing the system to follow highly accurate feed.

Space Saving

Due to an integral structure where Linear Motion Guide units are placed on both side faces of the inner block and a Ball Screw unit is placed in the center of the inner block, a highly rigid and highly accurate actuator with a minimal space is achieved.

Caged Ball Technology

High Speed

Model SKR supports a latest high-rotation servomotor (6,000 min-1) by using a ball cage and is capable of operating at higher speed than the full-ball type model KR. Models SKR33/55/65 are available in more leads variations to achieve higher speed operation and high leads are available which was not feasible with the model KR.

|

Model No.

|

Lead

|

|

SKR

|

KR

|

|

33

|

6,10,20

|

6,10

|

|

55

|

20, 30, 40

|

20

|

|

65

|

20, 25, 30, 50

|

25

|

High Lubricity

Model SKR uses ball cages to eliminate friction between balls and significantly improve torque characteristics. As a result, the torque fluctuation is reduced and superb lubricity is achieved.

|

Item

|

Description

|

|

Shaft diameter/lead

|

ø 13/10mm

|

|

Shaft rotation speed

|

60min-1

|

Low Noise, Acceptable Running Sound

In model SKR, the use of a ball cage in the Linear Motion Guide section and Ball Screw section (excluding models SKR20/26) has eliminated collision noise between the balls. As a result, low noise and acceptable running sound are achieved.

Long-term Maintenance-free Operation

With model SKR, the ball cage effect helps increase grease retention and achieve long-term maintenance-free operation.

Long service life-3 times

With model SKR, both the Linear Motion Guide unit and the Ball Screw unit have larger basic dynamic load ratings than the full-ball type model KR, and therefore a longer service lives are achieved. The rated service life is calculated from the following equation.

|

Linear Motion Guide unit

|

Ball screw unit

|

|

L10 = (C/P)3×50

L10: Nominal life (km)

C : Basic dynamic load rating (N)

P : Applied load (N)

|

L10 = (Ca/Fa)3×106

L10: Nominal life (rev)

Ca : Basic dynamic load rating (N)

Fa : Applied axial load (N)

|

As indicated in the equation above, the greater the basic dynamic load rating, the longer the service life of both the Linear Motion Guide unit and the Ball Screw unit.

Seal

Model SKR is equipped with end seals and side seals for dust prevention as standard.