Nội dung

Nội dung

About the Customer

SANYO KASEI (THAILAND) LTD. is the Thai subsidiary of Sanyo Chemical Industries, a Japanese chemical group specializing in surfactants and superabsorbent polymers.

This company requires extremely high reliability in measurement and analysis, particularly for quality control processes. Liquid viscosity measurement is one of the critical parameters in its quality assurance operations.

Challenge: Limitations of Manual Viscosity Measurement

Previously, the customer used a traditional manual method for viscosity measurement:

- Capillary viscosity measurement, recording the time required for liquid to flow between two defined reference marks.

- Operators visually observed the liquid surface passing the upper and lower marks inside a temperature-controlled bath.

- A stopwatch was used to measure the elapsed time.

Viscosity is measured by timing how the liquid flows from the upper reference line to the lower reference line

Due to its manual nature, this method presented several key limitations:

- Measurement variability and poor repeatability caused by operator dependency.

- Operators could not perform other tasks during measurement. If the end point was missed, the test had to be repeated from the beginning.

- Significant time spent on manual calculation and data recording.

- Alternative viscosity measurement methods required expensive dedicated viscometers.

- Industrial cameras and conventional machine vision systems exceeded the available budget.

The customer aimed to optimize the inspection process, minimize human error, and automate viscosity measurement without investing in high-cost machine vision systems.

Solution

The MoMaVi image processing system was selected to address this challenge. MoMaVi is developed by Mars Tohken Solutions (Japan).

Key differentiators of MoMaVi include:

- Use of a smartphone camera instead of an industrial camera, with no need for dedicated lighting.

- Simple configuration, low investment cost, and easy deployment.

- Capability to handle a wide range of visual inspection tasks.

- High measurement accuracy despite significantly reduced system cost.

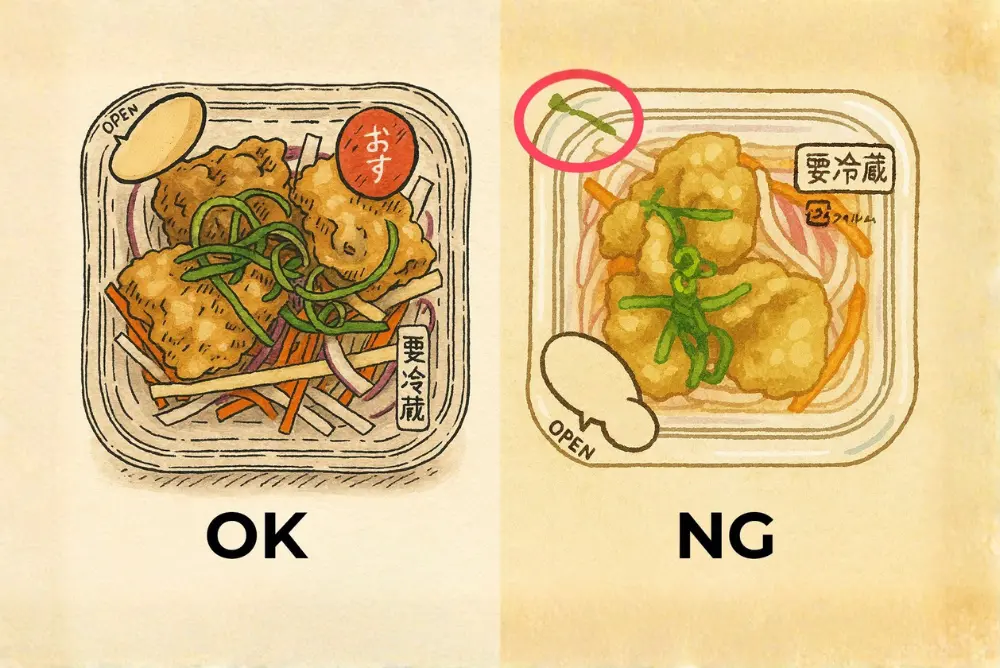

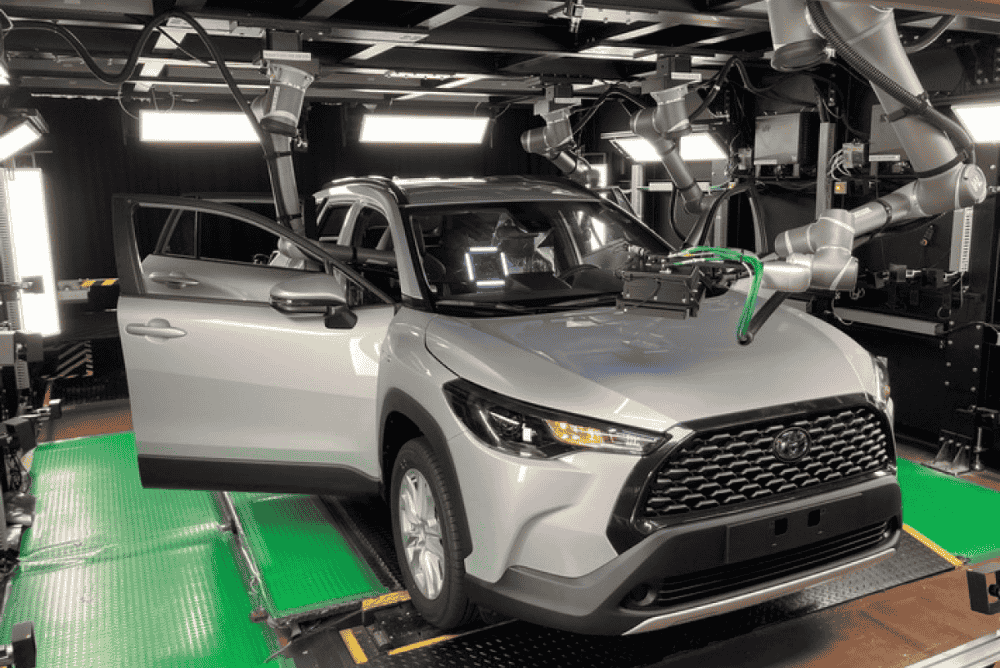

Core Inspection Capabilities of MoMaVi

- Presence and absence inspection

- Color sequence verification and color counting

- Quantity counting in boxes, pallets, etc.

- Pattern, logo, and printed mark inspection

- Surface inspection

- Shape inspection of plastic and metal parts

- Large-area inspection using a single camera

- Many other visual inspection applications

Some applications of the MoMaVi system

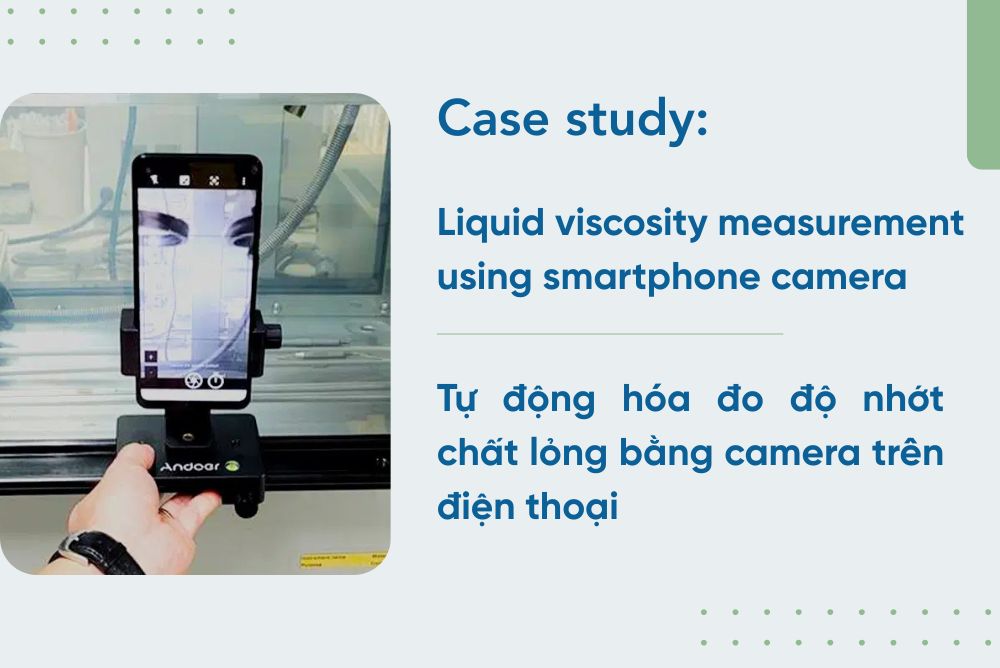

Application of the MoMaVi system for liquid viscosity measurement

In this specific application for SANYO KASEI (THAILAND) LTD., MoMaVi operates as follows:

- A smartphone camera is fixed in front of the temperature-controlled bath, continuously capturing images of the liquid surface.

- The image processing algorithm automatically detects when the liquid surface reaches the upper and lower reference marks.

- When the liquid reaches the upper mark, timing starts.

- When it reaches the lower mark, timing stops.

- Viscosity calculation is fully automated. After capturing the elapsed time, MoMaVi calculates viscosity automatically without manual data entry or external computing devices.

- The entire measurement and calculation process is performed automatically.

A smartphone camera is fixed in front of the temperature-controlled bath

The system automatically records the elapsed time and calculates the viscosity

Case study video:

Results

After implementing the MoMaVi image processing system, the previous issues were effectively resolved::

- Elimination of measurement variability: The system automatically starts and stops timing with a resolution of 0.001 seconds. Results are highly repeatable and independent of operator skill or measurement count.

- Improved labor efficiency: Once the start button is pressed, MoMaVi handles the entire process automatically. Operators can perform other tasks in parallel without continuous monitoring, significantly improving productivity.

- No rework required: The risk of missing the measurement endpoint is completely eliminated.

- Automated calculation and data management: Viscosity data is transmitted directly to LIMS (Laboratory Information Management System) and used to issue COAs (Certificates of Analysis). This ensures laboratory-grade traceability and removes errors associated with manual calculations.

- Cost savings: By using a smartphone camera and image processing software instead of high-end vision inspection systems, the solution achieves high accuracy at a fraction of the cost.

Customer Feedback

Mr. Mitsuhashi, representative of SANYO KASEI (THAILAND) LTD., shared:

“When I first heard Mr. Shima explain the concept behind MoMaVi, I immediately thought of applying it to viscosity measurement. In the chemical industry, reliability is the most critical factor. However, humans inevitably make mistakes. A single error in analysis can lead to a loss of customer trust and place enormous pressure on the individual involved. I have witnessed this many time. Management should not place blame on individuals when analytical errors occur.

That is why we are extremely satisfied with the improvements delivered by MoMaVi, and we are now sharing this system model across the entire group. Based on the results of this case study, we plan to apply the system to new product inspections. We look forward to Mars Tohken continuing to provide advanced solutions that contribute to our business growth.”

Implementing the MoMaVi image processing system delivers the following advantages:

- Reduced pressure and error risk for laboratory personnel.

- Improved reliability and consistency of inspection data

- Allows management to focus on system-level improvements rather than assigning individual responsibility when errors occur.

From left to right: President Maeda and Mr. Mitsuhashi of SANYO KASEI (THAILAND) LTD., and Mr. Shima and Mr. Jihong of Mars Tohken

MoMaVi is a representative example of low-cost visual inspection automation that maintains high accuracy and strong data integration capabilities. The solution is particularly suitable for:

- Factories with limited budgets for dedicated machine vision systems

- Applications requiring elimination of human error in inspection and measurement

- Repetitive measurement processes prone to operator fatigue

- Manufacturing and laboratory environments that require clear data traceability

Related Content

Product: MoMaVi Image Processing System

Related blog:

- Reading Multiple Barcodes and OCR: Optimizing Production Management with MoMaVi

- Case Studies: How MoMaVi Enhances Inspection Automation

- MOMAVI - A Superior AI Vision System for Image Inspection Applications

Temas provides a wide range of machine vision and image processing solutions tailored to different budgets and technical requirements, including MoMaVi, IDS industrial cameras, the Visco image processing system, etc.

Contact us for a free consultation and an on-site demo at your factory.

![MOON LIFTER - SUCCESS STORY OF ONCHI SHOKUHIN CO., LTD. [KYOTO]](https://www.temas.vn/filemanage/Case Stories/Unipulse/Moon Lifter/cau_chuyen_thanh_cong_moon_lifter_3.jpg)

Read more

Read more