Contents

Contents

Seal Integrity – A Critical Factor in Ready-to-Eat Food Production

In the ready-to-eat food industry, the tightness of the package seal is a vital factor that determines product freshness, quality, and hygiene. Even the smallest error during the top-sealing process can cause leakage, contamination, or spoilage—leading to substantial financial losses and damaging consumer trust.

This was exactly the challenge faced by トオカツフーズ株式会社 – TOKATSU FOODS Co., Ltd. (Toukatsu Foods), one of Japan’s leading manufacturers of ready-made meals.

Toukatsu Foods specializes in bento boxes, onigiri (rice balls), sandwiches, prepared meals, and frozen food products. With a vast production network and tens of thousands of meal boxes processed daily, manually inspecting each package after sealing posed significant challenges in terms of manpower, speed, and accuracy

The Problem: Sealing Errors in the Top-Seal Process

In Toukatsu Foods’ high-speed packaging lines, the top-sealing process is designed for rapid throughput. However, small pieces of ingredients—such as lettuce leaves, onion slices, or noodles—can occasionally become trapped between the plastic lid and tray during sealing.

These seemingly minor issues can lead to serious consequences:

- Air or liquid leakage, compromising the seal integrity and freshness.

- Hygiene and safety risks, reducing shelf life and increasing the likelihood of spoilage.

- Lack of traceability, as no inspection data is recorded for later review.

In addition, manual visual inspection proved unreliable over time. Human operators often experienced fatigue and reduced focus during long shifts, leading to overlooked defects. Transparent or light-colored ingredients such as onions or leafy vegetables further complicated visual detection, as they blended with the packaging background.

With such mass production volume, even a small defect rate could result in hundreds of defective products each day — highlighting the urgent need for a fully automated, stable, and intelligent inspection system.

Technical Challenges

Despite employing conventional camera-based inspection systems, Toukatsu Foods continued to encounter several technical limitations:

- Low contrast and transparent materials: Ingredients like onions or young greens do not reflect light clearly under transparent plastic lids, making it difficult for traditional algorithms to detect them.

- Varied shapes and colors of food: Hundreds of toppings, sauces, and ingredients require a highly adaptive recognition model

- Real-time image processing synchronization: The high-speed conveyor demands the AI system to capture, analyze, classify, and send control signals instantaneously without disrupting the production flow.

- Extensive training data requirements: To achieve reliable detection, the AI needs a diverse dataset of OK/NG images under various lighting and product conditions—an additional challenge in the early implementation phase.

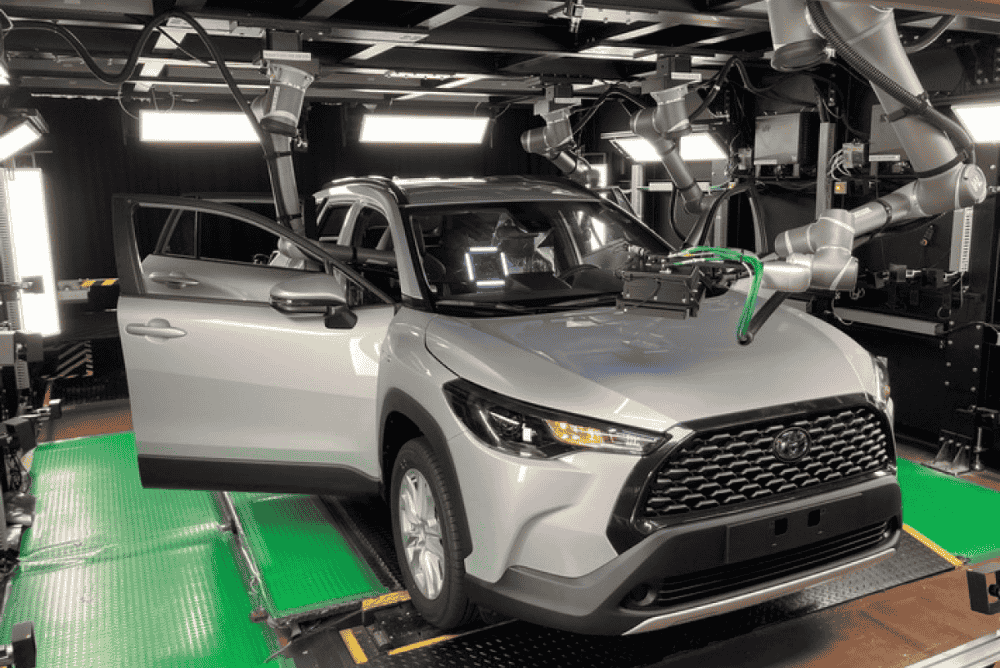

The Solution: Techman AI Vision Inspection

To overcome these challenges, Toukatsu Foods adopted an AI-powered Vision Inspection System developed by Techman Robot. The solution features the Techman AI Cobot—a collaborative robot equipped with a powerful integrated machine vision and AI inspection system.

The System

- An industrial camera mounted above the conveyor captures images of the sealing area for each packaged meal.

- The embedded AI Vision module inside the Techman robot analyzes each image using an AI Classification model to determine whether any foreign material is trapped in the seal zone.

- When a defect (NG case) is detected, the system instantly sends a signal to the PLC, prompting the robot to remove the defective product from the line in real time—without interrupting production speed.

AI Classification Model

Among Techman’s suite of AI Vision tools—AI Anomaly Detection, AI OCR, AI Object Detection, AI Semantic Segmentation, and AI Classification—the AI Classification model proved the most effective for this packaging inspection task.

How it works:

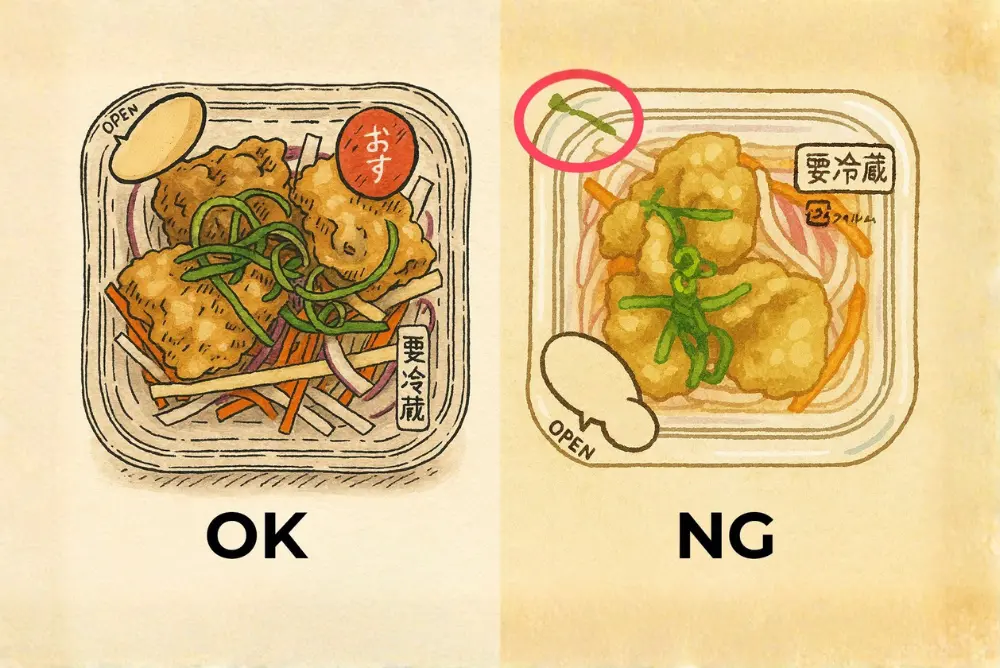

- The AI model is trained on labeled image data (OK or NG).

- OK images: properly sealed trays with no trapped material.

- NG images: samples with ingredients or foreign objects caught between the tray and film.

- After a short training phase, the AI can automatically identify abnormalities—even when variations in color, brightness, or ingredient shape appear that were not included in the original dataset.

This intelligent approach significantly reduces manual workload, eliminates human error, and maintains high inspection accuracy in continuous production environments.

Results and Key Benefits

By integrating Techman’s AI Vision Inspection System, Toukatsu Foods not only solved its sealing defect problem but also gained multiple long-term advantages:

- Easy training – no complex coding required: Techman’s intuitive drag-and-drop software interface and powerful AI server enable quick deployment and easy adaptation for production teams.

- High inspection accuracy: The Deep Learning-based AI Vision continuously improves through real production data, achieving exceptional precision—even detecting transparent materials like onion slices, which are nearly invisible to the human eye.

- Reduced reliance on manual labor: The automated system operates 24/7, eliminating fatigue-related mistakes and ensuring consistent quality.

- Real-time defect removal: NG products are identified and ejected immediately, keeping the production flow uninterrupted.

- Cost savings and compact integration: Camera, AI, and robotic arm are all housed within one Techman system—minimizing hardware cost, floor space, and installation time compared to multi-system setups

- Traceability and quality tracking: All inspection images and results are stored for easy review, quality audits, and traceability

- Scalable and flexible: The AI model can be retrained and extended to inspect other packaged products such as bento meals, noodles, sauces, or confectionery.

Techman AI Vision offers versatile applications across multiple use cases and industries

AI Vision: Redefining Quality Control in Food Manufacturing

The success of Toukatsu Foods demonstrates how automation and artificial intelligence can revolutionize quality assurance in the food industry

With Techman AI Vision Inspection, manufacturers can now ensure packaging integrity, enhance food safety, and optimize productivity—all while reducing costs and human workload.

More info: Key technologies of Techman AI Cobot (New)

In Vietnam, Temas is the authorized distributor and technical consultant for Techman Robot. We provide end-to-end solutions that help manufacturers accelerate their journey toward intelligent automation.

Temas offers:

- Integrated Techman Cobot with AI Vision systems for automatic visual inspection.

- AI model training tailored to real factory products.

- Consulting and implementation of AI Vision Inspection for packaging, pharmaceuticals, components, and food industries.

👉 Contact Temas for a detailed consultation on AI Vision Inspection and smart robot solutions for your factory.

![MOON LIFTER - SUCCESS STORY OF ONCHI SHOKUHIN CO., LTD. [KYOTO]](https://www.temas.vn/filemanage/Case Stories/Unipulse/Moon Lifter/cau_chuyen_thanh_cong_moon_lifter_3.jpg)

Read more

Read more